|

|

|

|

|

| Characteristics |

|

| 1) |

High rigidity unified steel sheet straight side frame construction allows for high speed, high precision manufacturing with excellent durability and endurance. |

| 2) |

With the transfer feeder equipment stable conveyance and higher productivity is accomplished during high-speed operation. (Transfer conveyor and blank pusher have different timings) |

| 3) |

the impact of the eccentric load is minimized. It has been realized by a connecting rod to fit inside the processing stage of all. and Influence of the eccentric load stays minimized by this effect. And die life is greatly prolong life by the Synergistic effect of the characteristics of 1). |

| 4) |

The upper die component can be adjusted before each step due to separate construction and height can be easily fine-tuned before each step (1/100 gradations) |

| 5) |

Oil supply, air pressure, miss-grip, feed bar, pusher, and safety guard use interlocking attachment for assured safety during production. |

| 6) |

At each stage the upper knockout can be adjusted between mechanical or air operation, and with mechanical operation timing can be adjusted. |

| 7) |

With air combination clutch and brake equipment stabilized production can be achieved during high-speed operation. |

| 8) |

Each part has a compulsory lubrication system, and just-in-case a stick removal mechanism is included. |

|

|

|

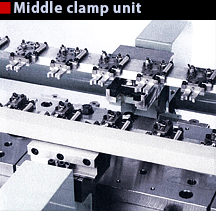

| The middle clamp unit apparatus is set in the center of the machine in order to remove play and bending of the feed bar to achieve safe conveyance during high speed operation. |

|

|

|

| Columns 1,2,3, and 4 are easily interchanged so production start-up is as easy as programming the number of blanks and columns to be used. |

|

|

|

|

|

| We have improved the operations console for greater functionality and ease of use. The result is more efficient safety for the machine, die components, and the operator. The internal mis-feed monitor stops the machine immediately and alerts the operator of the problem. |

|

|

| In the case of an overload, this is a feature which will protect the machine and the die from damage. |

|

|

|

| Die cushion : |

generally used for raising processes. |

| Lift-up cushion : |

Raises the forged material to the feeding level. |

| Hydraulic upper knockout : |

Contributes to the precision of the processed material. |

| Wax supply pump : |

Specialized wax for raising processes which simultaneously cools and lubricates the die component. |

| Air ejector, Uncoiler |

|

|

|

|

|

| Standard specifications |

| * |

Basic specifications for all models, but alterations can be made to request. For more details please contact us and we will be flexible in making adjustment to meet your demands. |

|

|

| Model |

MTP-450-14HB |

MTP-450-14HC |

MTP-600-14HB |

MTP-600-16HBK |

MTP-800-16HB |

MTP-1000-18HB |

| Pressure/total processes |

45ton |

45ton |

60ton |

60ton |

80ton |

100ton |

| Pressure at each stage |

10ton |

13ton |

13ton |

10ton |

14/ First stage only 20ton |

13ton/16ton(special specification) |

| Stroke length |

140mm |

100mm |

160mm |

140mm |

190mm |

190mm |

Stroke number

(can be adjusted) |

40~150spm |

40~200spm |

40~120spm |

40~100spm |

35~100spm |

35~80spm |

| Die height |

280mm |

280mm |

350mm |

310mm |

420mm |

450mm |

| Upper die adjustment |

20mm |

20mm |

30mm |

30mm |

30mm |

30mm |

| Shank hole diameter |

φ32 |

φ40 |

φ40 |

φ38 |

φ50 |

φ38 |

| Processes |

14 |

13 (actual) |

14 |

16 |

15 (actual) |

18 (actual) |

| Bolster surface(LR×FB) |

1,500×380mm |

1,500×380mm |

1,730×450mm |

1,730×450mm |

2,250×540mm |

2,250×540mm |

| Bolster thickness |

60mm |

90 |

100mm |

150mm |

100mm |

100mm |

| Feed stroke/mould area pitch |

100mm |

100mm |

120mm |

100mm |

130mm |

120mm |

| Clamp stroke (one side) |

50mm |

50mm |

60mm |

55mm |

70mm |

70mm |

Feed bar internal width

(when clamped) |

120mm |

140mm |

150mm |

140mm |

160mm |

180mm |

Feed level

(to the bottom of the bar) |

130mm |

132mm |

180mm |

130mm |

222mm |

252mm |

| Feed bar cross section dimensions |

60×20mm |

60×20mm |

70×25mm |

70×25mm |

75×25mm |

75×25mm |

| Feeding direction |

left to right |

left to right |

left to right |

left to right |

left to right |

left to right |

| Maximum blank diameter |

φ80 |

φ80 |

φ100 |

φ80 |

φ100 |

φ100 |

| Maximum raising thickness |

47mm |

33mm |

55mm |

47mm |

63mm |

63mm |

| Air pressure |

0.5Mpa |

0.5Mpa |

0.5Mpa |

0.5Mpa |

0.5Mpa |

0.5Mpa |

| Main motor |

15kw×4p |

22kw×4p |

15kw×4p |

22kw×4p |

37kw×4p |

37kw×4p |

Machine Dimensions

(LR×FB×H) |

2,830x1,280

x2,873mm |

2,830x1,280

x

2,893mm |

3,230x1,580

x3,600mm |

3,260x1,580

x3,600mm |

4,435x2,000

x3,810mm |

4,447x2,000

x3,810mm |

| Weight |

7.6ton |

8ton |

15ton |

15ton |

23ton |

23ton |

|

|

|

|

|

|